Eggs are a daily part of our meals — from breakfast omelettes to cakes, desserts, and snacks. But have you ever wondered how eggs are selected, sorted, and packed before they reach your kitchen? Not all eggs are the same. Some are fresher, stronger, and richer in nutrition compared to others.

This is where egg grading comes in — a quality control process that ensures only the best eggs reach consumers.

What is Egg Grading?

Egg grading is the process of examining and sorting eggs based on their quality, both from the outside (shell condition) and inside (yolk and egg white quality). Grading ensures:

- Better food safety

- Superior taste and cooking results

- Fair pricing in markets

- Confidence and trust for consumers

Why is Egg Grading Important?

| Benefit | Why It Matters |

|---|---|

| Hygiene & Safety | Removes dirty or cracked eggs that may carry bacteria. |

| Consistent Quality | You get the same good quality every time. |

| Better Nutritional Value | Higher-grade eggs generally have better yolk and albumin strength. |

| Enhances Brand Trust | Customers recognize reliable egg suppliers. |

How Are Eggs Graded?

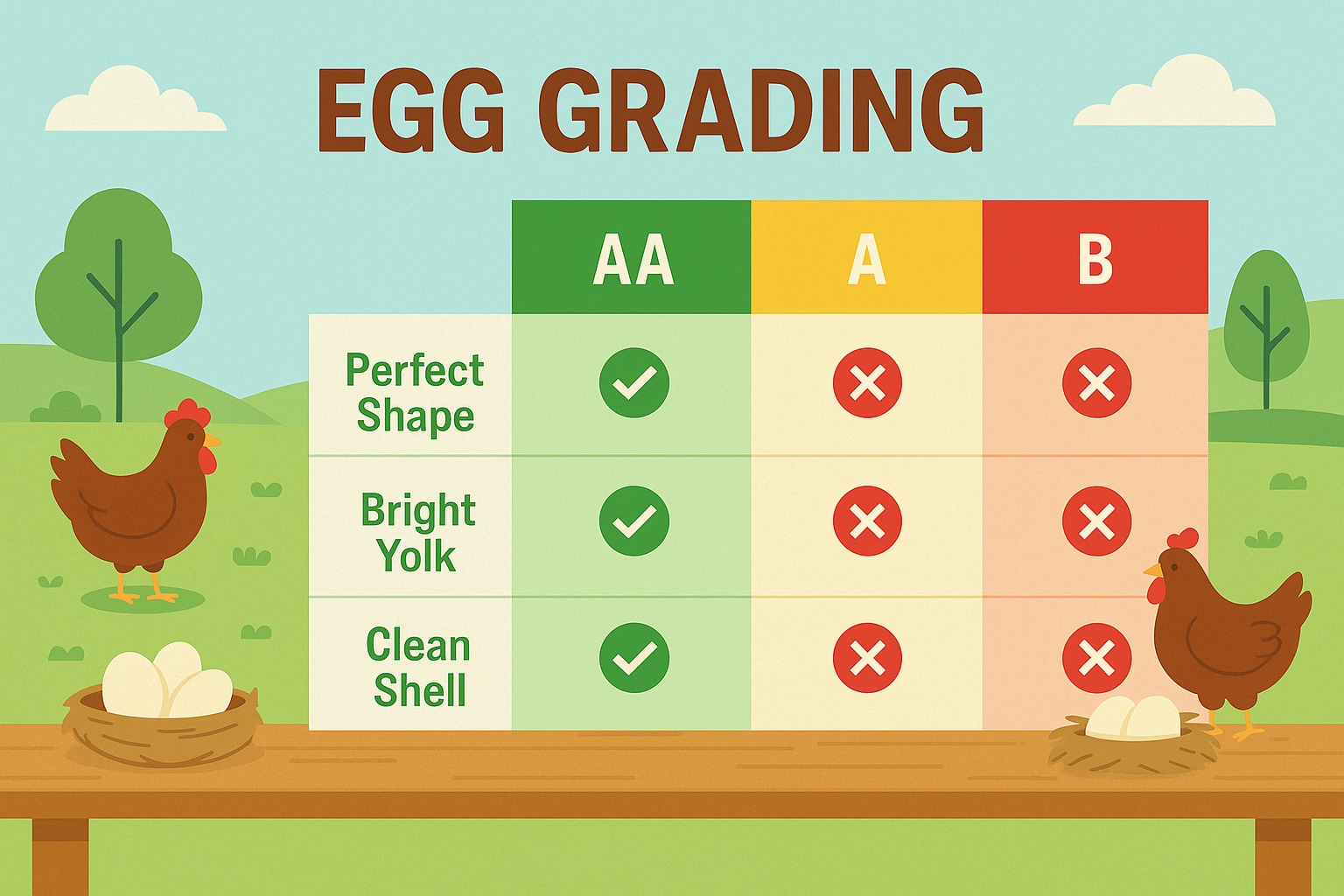

Eggs are usually graded into three main quality grades:

🥚 Grade AA (Superior Quality)

- Perfectly shaped eggs

- Strong, clean, crack-free shell

- Thick and firm egg white

- Round, bright yolk that stands tall

These are considered premium eggs and ideal for households and restaurants.

🥚 Grade A (Good Quality)

- Clean shell but shape may vary slightly

- Yolk may be less firm than AA

- Good for general cooking and daily use

🥚 Grade B (Industrial Grade)

- Shell may have stains or slight irregularities

- Yolk may be flatter, white thinner

Often used for:

- Bakeries

- Liquid eggs

- Egg powder production

Criteria Used in Egg Grading

| Quality Check | What Is Evaluated | Ideal Characteristics |

|---|---|---|

| Shape | Uniformity of egg shape | Oval, smooth contour |

| Shell Strength | Thickness and crack resistance | Strong, clean shell |

| Cleanliness | Dirt / marks presence | Spotless exterior |

| Yolk Quality | Height, color, firmness | Round, centered, golden yolk |

| Albumen (Egg White) | Thickness and viscosity | Thick, not watery |

✅ Higher quality = Higher freshness.

How Farmers & Suppliers Perform Egg Grading

Egg grading can be done:

- Manually — by trained workers visually inspecting eggs.

- By Candling — shining a light through the egg to check internal quality.

- By Automated Machines — used in modern poultry farms to sort eggs rapidly based on weight, shell quality, and internal condition.

What Does This Mean for Consumers?

When you buy eggs, look for:

- Clean shell with no cracks

- Natural shell shape (not too round, not too long)

- Freshness test: place egg in water — fresh eggs sink; old eggs float.

Fresh eggs taste better, hold shape better while cooking, and are safer to consume.

Egg Grading Supports Better Farming Practices

For brands and suppliers:

- Grading reduces food waste

- Ensures higher customer satisfaction

- Helps establish product trust and reputation in the market

For example, Mahendra Feeds follows systematic egg grading to supply consistent, hygienic, nutritious eggs to households and businesses across regions.

Conclusion

Egg grading is not just a sorting process — it is an assurance of:

- Quality

- Safety

- Nutrition

- Freshness

So the next time you crack an egg, remember — it has gone through careful checks to ensure it's the best for you and your family.

At Mahendra Feeds, we ensure every egg meets the highest grading standards, delivering quality from our farm directly to your kitchen.